Energy efficiency and consumption in the brewery sector

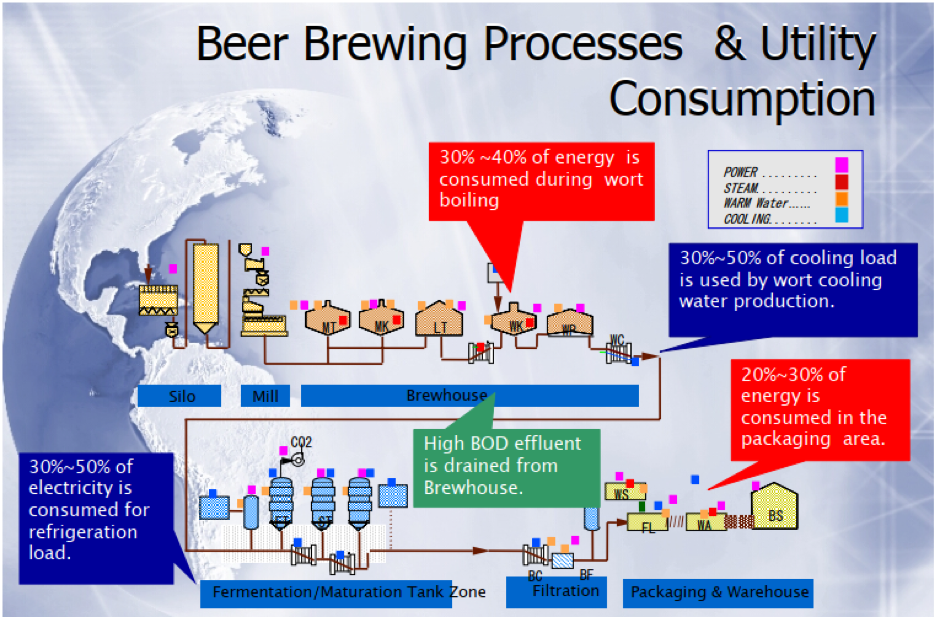

There are many processes involved in the manufacture of beer that involve the use of thermal energy, usually generated by burning oil, gas or coal and assisted by using electricity from the grid to drive pumps, motors, compressors and fans and direct heating of process streams.

The brewing process is energy intensive, with 30% to 50% of the energy in the form of electricity used for the cooling of the “wort,” the liquid extracted from the grain mashing process. Another 30% to 50% is used for cooling the fermentation tanks.

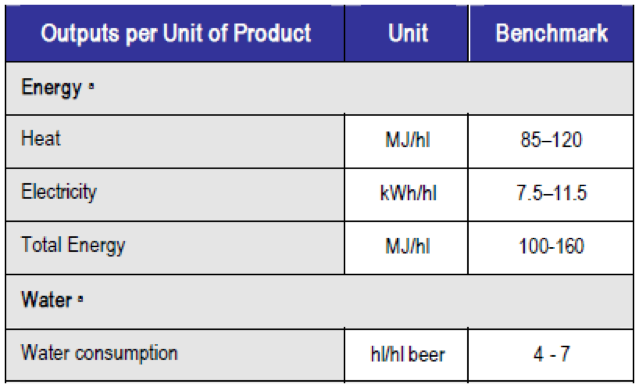

The efficiency of electricity use in the various brewing processes is traditionally measured in terms of the amount of energy used in kilowatt hours or KWh per hectolitre or (hl) of beer produced or kWh/hl as shown on the table below. Thermal energy usage is measured in mega joules of energy used per hectolitre or MJ/hl.

Click here to view one of our energy efficiency projects in the brewery sector.

Benchmark Specific Energy Consumption for the heat and energy usage of a typical brewery

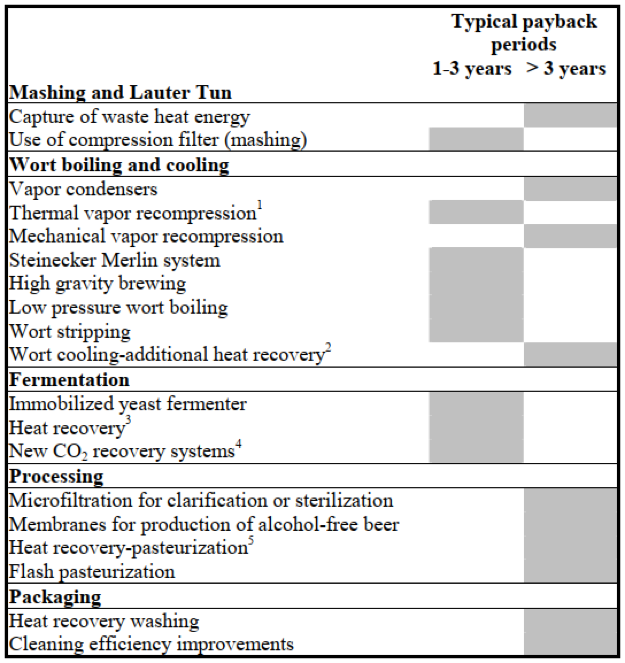

Energy saving opportunities in the brewery industry

Our services

Below are the energy efficiency services we provide. Contact us for more information on these services.

Comprehensive energy audit

Maximpact’s energy audit will cover all thermal and electrical process plant and utility systems. Our comprehensive energy audit specification will provide you with a detailed specification of our services and energy-saving potential, which is typically between 20% and 40% of your existing energy bills.

Data mining and process optimisation opportunities audit

Data mining can uncover a wealth of energy and process saving opportunities in your industry. Maximpact’s ability to uncover patterns of inefficient energy use or poor process performance and predict the energy-saving potential of utility and process improvements will provide you with a winning competitive edge. We can provide a first step study that offers a gap analysis and recommendations as to the measures you need to take now to avail yourself of this new technology and the type of artificial intelligence systems and approach that would be best applied to your process and utility systems.

New equipment energy efficiency specification

Are you considering purchasing a new two-stage refrigeration plant or a new steam boiler?

If so, we can help ensure that your vendors provide you with efficient equipment that will save on its running cost over its entire lifetime. You will be able to include energy efficiency specifications in your tender documents that will level the playing field for all bidders.

Perform an energy management system gap analysis

We will study your existing energy management practices by doing an analysis of the gap between where your systems are today and your future goals for your operation.

We help you to determine what steps you need to take to implement an energy management system such as the international energy standard ISO 50001. This standard makes it easier for organizations to integrate energy management into their overall efforts to improve quality and environmental management.

Training in energy awareness

Provide employee training in energy awareness associated with good plant operational practices.

ISO 50001 full implementation support

We provide support for full implementation of the energy management systems ISO 50001 in your factory.

Feasibility study

Provide for a feasibility study for the use of a combined heat and power system on the site.

Plant resilience audit and recommendations action plan

How prepared are your manufacturing processes to cope with weather extremes caused by global warming?

Can your manufacturing and utility systems cope with climate extremes such as that seen recently in the United States where a polar vortex extending over northern parts of the country in late December 2022 came with temperatures as low as -50⁰C?

The purpose of our resilience study is to determine how exposed your manufacturing and utility systems are to the extremes in weather variations that will be more commonly experienced throughout the world due to climate change.

These extremes are occurring right now. In the past, it was common practice to design for specific minimum low, ambient low, and high temperatures based on weather statistics averaged or typically 50 to 100 years. Global warming has changed these statistics, but many design engineers have not kept up with the changes.

We have formulated an approach to assess your process and utility systems and their resilience to climate change. Don’t wait until your vulnerabilities are revealed by weather extremes, resulting in the costs of lost production and product output. Act now and be prepared.

Renewable Energy for the Brewery Sector

- A feasibility study of the installation of solar thermal water heating for domestic hot water usage.

- A feasibility study on the potential for using geothermal energy to provide for domestic hot water and space heating needs.

- A feasibility study of the installation of Solar PV systems to displace imported grid power.

- A feasibility study for utilising a renewable energy boiler to produce domestic hot water and for process heat using biofuels such as wood pellets or another renewable energy source.

- A feasibility study of installing a co-generation or tri-generation systems to supply electricity, heating and high cooling for the fermentation and processing and storage of beer.

- A feasibility study of using waste brewers yeast from the fermentation process to produce methane gas in an anaerobic digester unit. This methane can run co-generation or tri-generation systems to replace expensive grid power and supply hot water, steam and cooling water to the brewing processes.